Moving bed biofilm reactors (MBBR)

Our MBBR is a factory-assembled, easy-to-install biological oxidation wastewater treatment system designed for small requirements of up to 500 PE using a single module.

Bespoke solutions

Bespoke solutions

Compact and discreet

Compact and discreet

Peace of mind

Peace of mind

360° support

360° support

What is an MBBR?

A moving bed biofilm reactor (MBBR) system is perfect for treating wastewater from commercial, institutional, or industrial buildings with frequent changes in discharge flow rates and organic load concentrations.

This biological treatment system uses plastic biofilm media, which are added to the reactor to increase its biomass density. The design is thus more compact and has better and more reliable performance.

Our Rewatec MBBR system uses high-density polyethylene (HDPE) tanks. Each tank is quick and easy to install because we pre-assemble internal blowers, electrical components, and electrical connections in our factory.

Typical applications

- restaurants

- service stations

- wineries and breweries

- commercial areas

- agrifood plants

- commercial or municipal buildings

- small communities

How does the Rewatec MBBR system work?

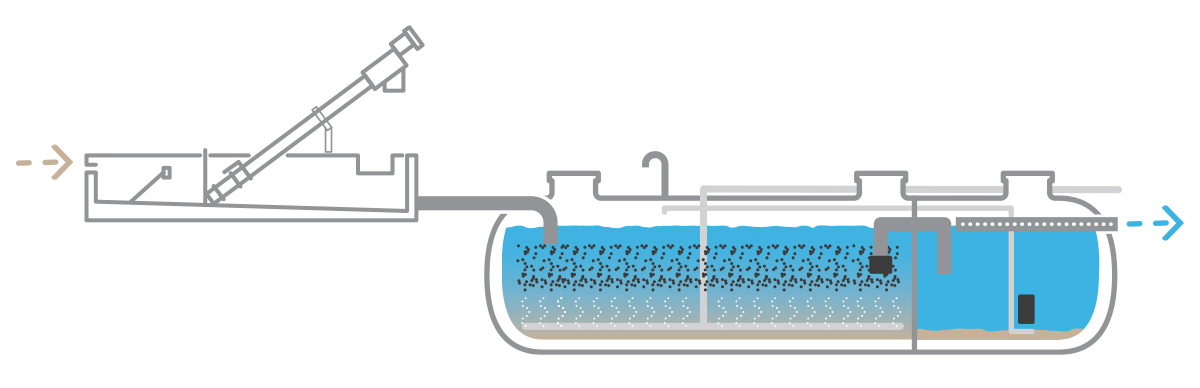

Automatic screen followed by a primary treatment reactor

In typical installations, wastewater first flows into an automatic screen to remove large solids. Effluent then flows into the primary treatment reactor, which allows liquids and solids to separate. The resulting scum and sludge must be removed regularly.

Equalisation chamber (if necessary)

After primary treatment, liquids may flow into an equalisation chamber that collects wastewater from daily peak-use periods and flushes controlled doses into the Rewatec MBBR reactor. This step could be included in the primary treatment chamber if the design allows it.

Rewatec MBBR reactor

Inside the Rewatec MBBR reactor, microorganisms grow in a fine biofilm over plastic media. These microorganisms consume organic pollutants in the wastewater, resulting in effluent composed of biomass particles and treated wastewater.

The shape of our plastic media increases the surface area on which microorganisms can attach and grow. This maximises their capacity to treat wastewater and helps reduce the size of the MBBR reactor.

The MBBR reactor is continuously agitated with bubbles from an aeration system. This system mixes the contents of the MBBR reactor to promote aerobic digestion. Again, this improves the capacity of microorganisms to remove pollutants from wastewater.

Clarification chamber and final discharge

Wastewater then flows into the clarification chamber, where liquids separate from any biomass that still exists after treatment.

Sludge is returned to the primary treatment reactor or to an accumulation tank to be subsequently pumped out. If no further treatment is needed, effluent is then discharged into the environment in accordance with local regulations.

MBBR system maintenance

Premier Tech recommends that you follow maintenance instructions according to the model installed. Protect your investment, maximise its service life, and maintain your warranty by having your system regularly inspected.

If you need to check the condition of your Rewatec MBBR system, please feel free to contact us.

Rewatec MBBR system warranty

For more than 25 years, we have developed sustainable, long-lasting products that make a difference for our clients, our professional partners, and our planet.

Our experience allows us to offer the most comprehensive warranty in the industry, and to do it in an open and honest manner.

The Rewatec MBBR system warranty* includes:

- 5 years for polyethylene tanks manufactured by Premier Tech

- 2 years for control panels and pumps

- 1 year for blowers

- proper system functioning and performance, if maintenance is carried out by our team

* Equipment must be properly installed and maintenance must be carried out in accordance with Premier Tech’s guidelines and by certified maintenance teams.

Contact us

Contact our team of experts to learn more about sustainable solutions that improve the environment and our planet. Together we can make a difference.