Phosphorus removal

Protect public health and preserve sensitive ecosystems with our complete range of phosphorus removal options, specially designed to prevent harmful algae blooms in the lakes and rivers around your property.

Total protection

Total protection

Home and cottage systems

Home and cottage systems

Business and community systems

Business and community systems

What is phosphorus removal?

Phosphorus removal is a wastewater treatment option for properties in ecologically sensitive areas, where strict effluent standards are needed to protect lakes and rivers for future generations.

We offer phosphorus removal options for a wide range of residential, business, and community projects.

Each system safely isolates phosphorus compounds to ensure treated wastewater never contributes to harmful algae blooms in nearby watercourses.

Why is phosphorus removed from wastewater?

Phosphorus is a nutrient that is commonly found in wastewater. If it is discharged into the environment without proper treatment, it can enter nearby watercourses via groundwater or runoff.

Too much phosphorus causes an overabundance of algae in aquatic ecosystems. Algae blooms prevent sunlight from reaching native plants below the surface, resulting in their death. Bacteria that feed on decaying plant matter then increase in number, consuming more and more oxygen until larger species like fish and shellfish suffocate.

At this point, the once healthy watercourse can no longer support life. It becomes a dead zone.

The damage phosphorus can cause to our environment, health, and economy is dire.

- invasions of non-native species

- reduced biodiversity

- toxins in fish and shellfish

- human illnesses

- livestock poisoning

- reduced waterfront property values

- limited enjoyment of lakes and rivers

- lost revenues for commercial fisheries

The solution to this problem is simple: effective wastewater treatment systems that include one of our proven phosphorus removal options.

How do our phosphorus removal systems work for homes and cottages?

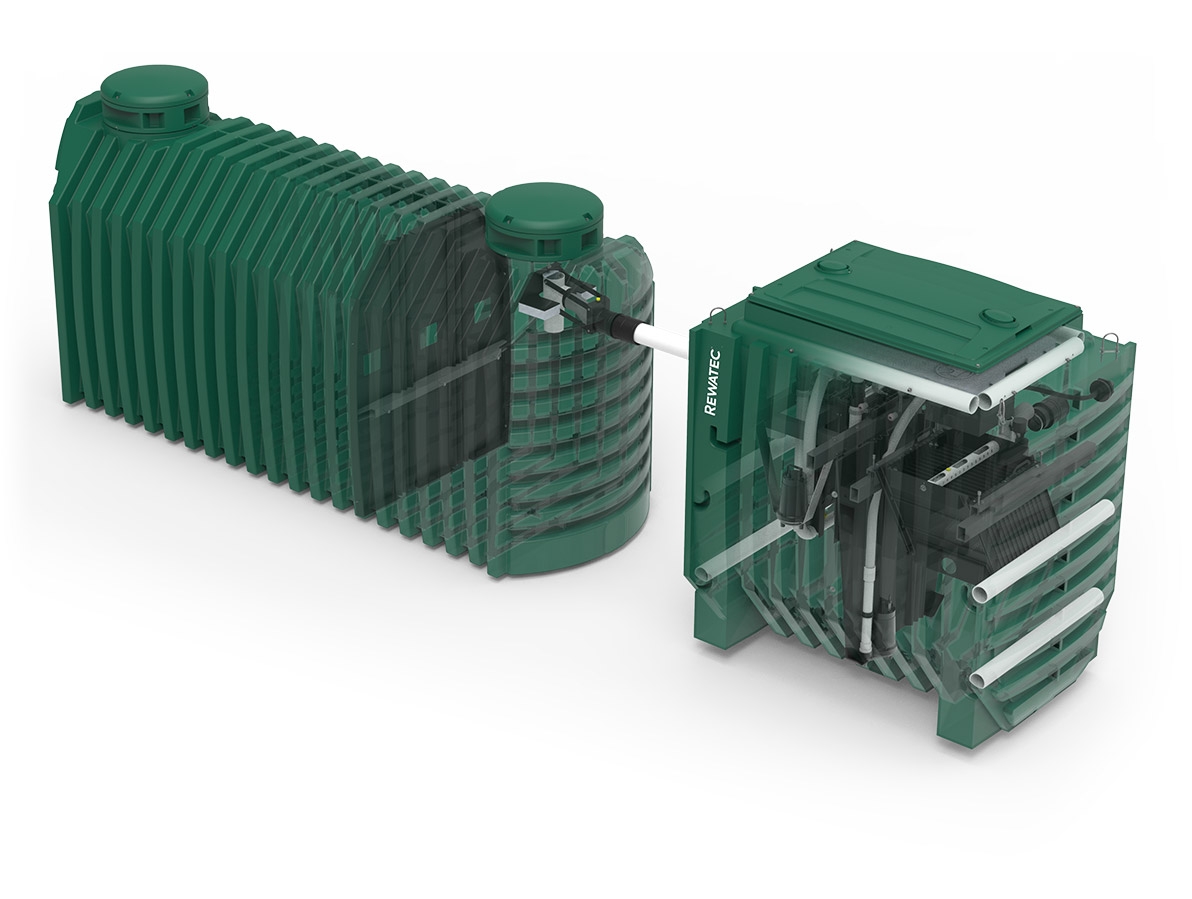

Primary reactor

Wastewater first flows into a primary reactor. Solids that settle on the bottom of the reactor are called sludge. They are removed from the tank by a septic pumper as often as needed.

Electrocoagulation unit

Liquids leave the primary reactor and flow downstream into an electrocoagulation unit. This unit has two chambers: a reaction zone and a separation zone.

In the reaction zone, electrodes release aluminum particles that react with phosphorus in wastewater. This process, called electrocoagulation, transforms soluble phosphorus into solid compounds.

In the separation zone, solid particles gradually settle on the bottom of the tank. They are then pumped back into the primary reactor for removal.

Additional treatment and final dispersal

As solids sink to the bottom of the separation zone, clarified wastewater forms at the top. Depending on local regulations, this wastewater flows downstream into:

- our Ecoflo biofilter (with the Rewatec UV disinfection unit)

- a sand filter

- a leach field

After final treatment, wastewater is discharged into a ditch or watercourse for final dispersal.

How do our phosphorus removal systems work for businesses and communities?

Our commercial, community, municipal, and industrial phosphorus removal options are ideal additions to our proven wastewater treatment systems:

- Ecoflo biofilter clusters

- Rewatec membrane bioreactor (MBR)

- Rewatec moving bed biofilm reactor (MBBR)

- Rewatec sequencing batch reactor (SBR)

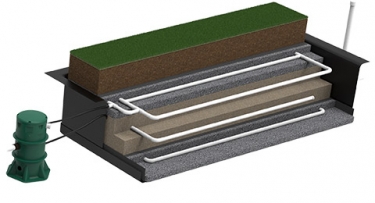

Coagulation

In all systems, dosing pumps inject coagulant into wastewater. The amount of coagulant is optimized based on the installation’s actual flow rates.

Coagulation takes place in a static mixer. The mixer allows wastewater to react with the coagulant, transforming soluble phosphorus into solid compounds.

If needed, additional injection points can be added at different parts of the treatment train to optimize and better control phosphorus removal performance.

Clarification and additional treatment

After coagulation, depending on the type of system used, solid phosphorus compounds either settle on the bottom of a primary tank or secondary clarifier, or they are blocked by a downstream filter.

These particles form sludge that is removed by a septic pumper as often as needed. Liquids, now with greatly reduced concentrations of phosphorus, continue downstream for additional treatment.

Phosphorus removal system maintenance for homes and cottages

We have a network of local service partners, trained by us to maximize the life of your residential Rewatec phosphorus removal system.

When a technician visits your property, they will:

- measure sludge in the primary reactor

- advise you if the primary reactor requires pumping

- ensure all components are operational

- inspect and clean the system’s flow regulator

- verify if aluminum electrodes need to be replaced

- collect samples to verify treatment performance (when required)

Phosphorus removal system maintenance for businesses and communities

Our network of technicians and local service partners is trained by us to maximize the life of your commercial, community, municipal, or industrial Rewatec phosphorus removal system.

When a technician visits your property, they will:

- inspect all system components

- measure sludge in sludge storage tanks

- check the flow rate of the pump to ensure coagulant is correctly dosed

- confirm that coagulant barrels are sufficiently full

- collect samples to verify treatment performance (when required)

Find near you

Choose your local website to discover Rewatec phosphorus removal products and services near you.