Grease interceptors

Total protection

Total protection

Simple to install

Simple to install

Minimal maintenance

Minimal maintenance

What is a grease interceptor?

A grease interceptor, also known as a grease separator, is a tank that receives wastewater containing fats, oils, and greases (FOG). The tank separates and traps FOG while allowing partially clarified wastewater to flow downstream for additional treatment.

Examples of FOG include:

- vegetable oil

- animal fat and grease

- butter and margarine

- dairy products

- gravy

- salad dressing

- mayonnaise

Without a grease interceptor, FOG solidifies and accumulates inside sewer pipes. This can lead to blockages, backups, and pipe bursts that damage property and spill untreated wastewater into the surrounding environment.

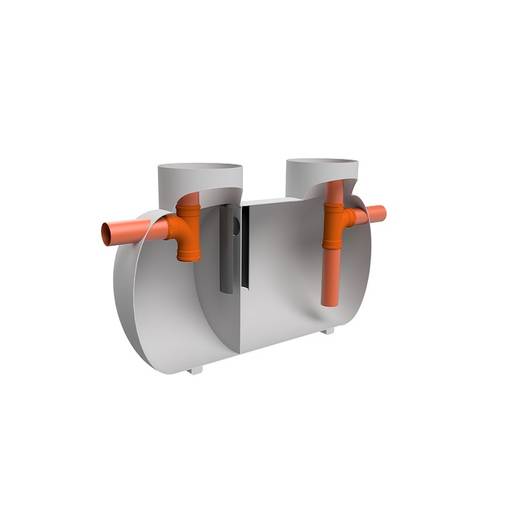

The Rewatec grease interceptor provides a simple solution. Designed for projects with medium to high flows, our autonomous systems offer total protection by effectively separating FOG from your wastewater. For added convenience, many models come pre-assembled and ready to use.

Where are our grease interceptors used?

The Rewatec grease interceptor is most often a solution for:

- restaurants and cafes

- bars and pubs

- hotels and guest houses

- hospitals

- schools

- food processing facilities

How do our grease interceptors work?

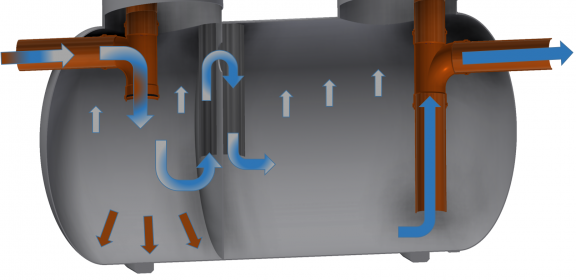

Wastewater from sinks, dishwashers, and other kitchen equipment runs into a main drainage pipe that flows into the two-chamber grease interceptor.

In the first chamber, solids settle on the bottom of the tank and form sludge. This sludge is removed by a septic pumper as often as needed.

In the second chamber, gravity separates fats, oils, and greases from wastewater. These substances naturally float to the surface and form scum. A system of baffles traps scum until it can be removed and transported for safe disposal.

A low-level pipe in the second chamber collects partially clarified wastewater and releases it downstream for further treatment.

Grease interceptor maintenance

Protect your property and the environment by having your Rewatec grease interceptor regularly pumped by a qualified service professional.

The frequency of service depends on the capacity of your tank, the amount of effluent you generate, and the environmental regulations in your area. It is best to speak with a local expert to determine the service schedule that is right for you.

Find near you

Choose your local website to discover Rewatec grease interceptor products and services near you.