Moving bed biofilm reactors

Pre-engineered and ready to use

Designs adapted to your needs

Components suited to your terrain

Manages flow and strength fluctuations

Performs in all seasons

Efficiency for lower operating costs

Smaller than traditional systems

Blends into your landscaping

Ideal when aesthetics matter

Dedicated project managers

Expert commissioning

Proven maintenance services

What is a moving bed biofilm reactor?

A moving bed biofilm reactor (MBBR) is the ideal solution for commercial, community, institutional, municipal, and industrial wastewater treatment projects with continuous fluctuations in flow and strength.

Suitable for flows of up to 5 mgd, Rewatec MBBR systems manage domestic and high organic loads in all seasons, reducing soluble CBOD5 by up to 99% and NH4 by at least 94%.

Where are our MBBR systems used?

Rewatec MBBR systems are most often solutions for:

- restaurants

- gas stations

- wineries and microbreweries

- hotels and inns

- campgrounds and parks

- food processing plants

- residential and municipal developments

- retrofits with existing infrastructure

How do our MBBR systems work?

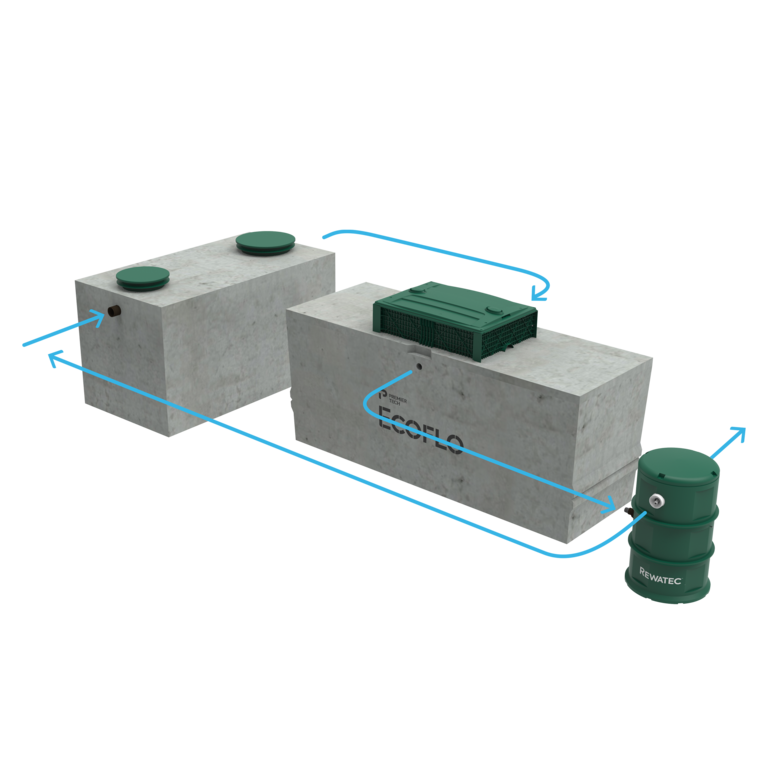

Primary treatment tank or fine screen

In typical installations, wastewater first flows into a primary treatment tank that allows liquids to separate from solids. Primary sludge that settles on the bottom of the tank is removed by a septic pumper as often as needed.

In some systems, a fine screen is used instead of a primary treatment tank. This simple barrier removes wastewater solids before they can move downstream.

Equalization tank (if needed)

After primary treatment, liquids move downstream and enter an equalization tank. This tank collects wastewater from daily peak-use periods and then sends controlled doses to the Rewatec MBBR.

Rewatec MBBR

Inside the Rewatec MBBR, microorganisms grow on floating biofilm carriers. They feed on organic wastewater pollutants, producing effluent composed of biomass particles and treated wastewater.

Our plastic biofilm carriers are specially shaped to increase the surface area on which microorganisms grow. This maximizes their ability to treat wastewater and helps you minimize the size of the reactor.

Bubbles continuously mix the contents of the Rewatec MBBR to ensure optimal contact between wastewater and microorganisms. Again, this improves their ability to remove wastewater pollutants.

Clarification tank and final discharge

After treatment in the Rewatec MBBR, wastewater flows into a clarification tank, where liquids are separated from biomass.

Sludge is sent back to the primary treatment tank or a sludge storage tank. Liquids are sent downstream for additional treatment or for safe discharge into the environment.

Premier Tech’s 360° support

Local expertise is the foundation of our global team. Together, we have the technical know-how and industry experience to make every phase of your project a success.

Design

- engineering support to guarantee the best solution

- help with technical drawings and diagrams

- advice for electromechanical equipment

- control panel design, including electrical diagrams

Construction and installation

- dedicated project managers

- fast answers to all questions

- on-site support to ensure high-quality installations

- real-time troubleshooting

Start-up

- commissioning by a qualified technician

- verification of installation success

- rapid responses to any areas of concern

Maintenance

- full support from our process and mechanical experts

- maintenance services from local technicians

- remote support available

Available models

Rewatec MBBR systems are available in a range of durable tank materials to meet your unique needs. Whatever your performance targets, we have the right model to transform any challenge into a personalized solution.

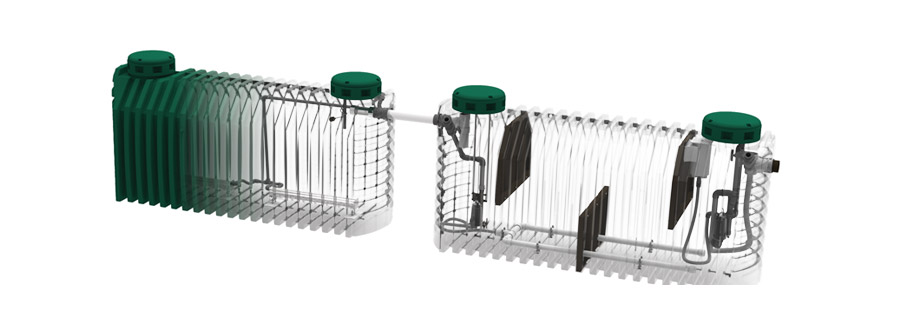

Solutions combining durability and versatility.

- modular systems tailored to your site

- ready-to-use models available

- compact and lightweight

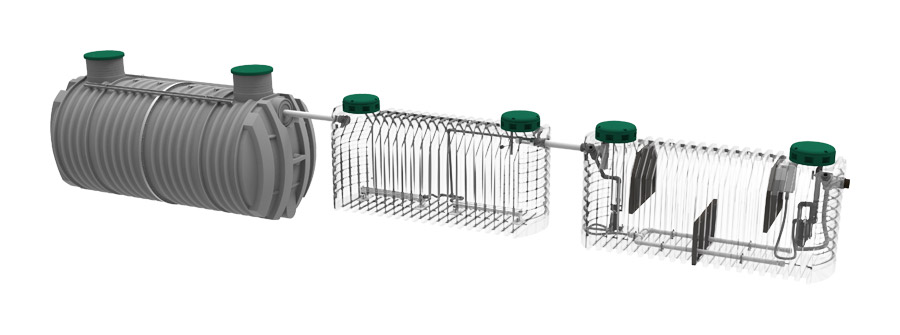

Ultra-robust solutions for all site conditions.

- cast in place or ready to use

- suitable for clay soils

- can be installed in high groundwater

Where lightweight materials meet robust design.

- ready-to-use models available

- minimal final footprint

- suitable for clay soils

- can be installed in high groundwater

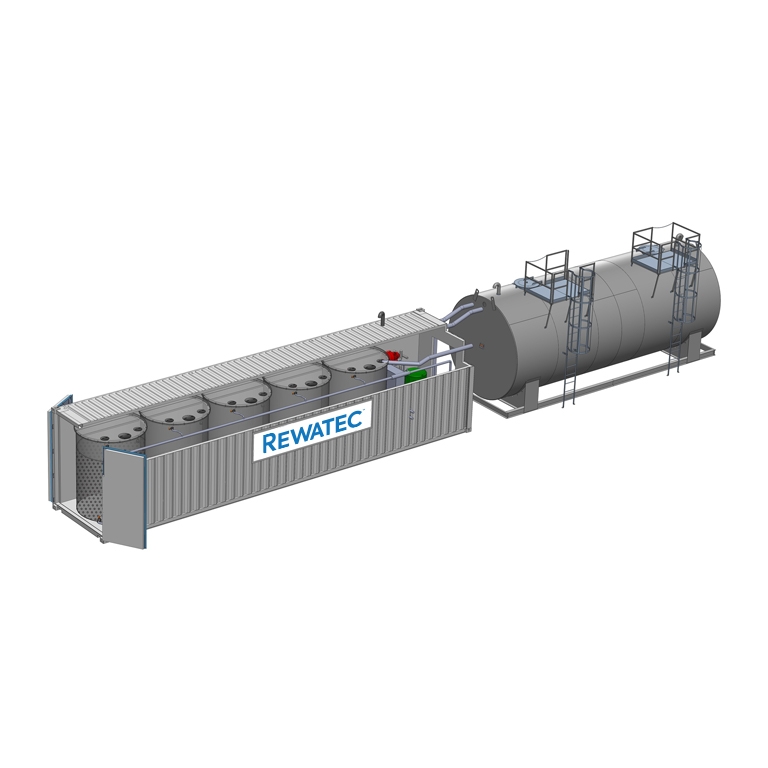

Solutions for remote projects and temporary camps.

- pre-assembled and ready to use

- easy set-up

- minimal infrastructure needed

- no excavation

Mobile solutions for remote projects and temporary camps.

- no lag between delivery and start-up

- pre-assembled and ready to use

- minimal infrastructure needed

- no excavation