Membrane bioreactors

Up to 75% smaller than other systems

Blends into your property

Odor-free effluent

Disinfects without UV

Removes nitrogen and phosphorus

Manages flow and strength fluctuations

Rigid flat sheet resists breakage

Pore uniformity increases flux rate

Sustains high pressure

Dedicated project managers

Expert commissioning

Proven maintenance services

What is a membrane bioreactor?

A membrane bioreactor (MBR) is a compact, highly effective solution for commercial and municipal wastewater treatment projects near ecologically sensitive areas.

Suitable for flows of up to 1 mgd, Rewatec MBR systems use a unique ultrafiltration membrane to block fecal coliforms and other wastewater pathogens.

The membrane has pores that are just 0.4 µm wide, making it so effective that treated effluent can be reused for non-potable applications (where allowed).

Where are our MBR systems used?

Rewatec MBR systems are most often solutions for:

- residential developments

- municipal developments

- schools

- campgrounds and parks

- roadside rest areas

- work camps

- sites near ecologically sensitive areas

- installations with faulty membranes

How do our MBR systems work?

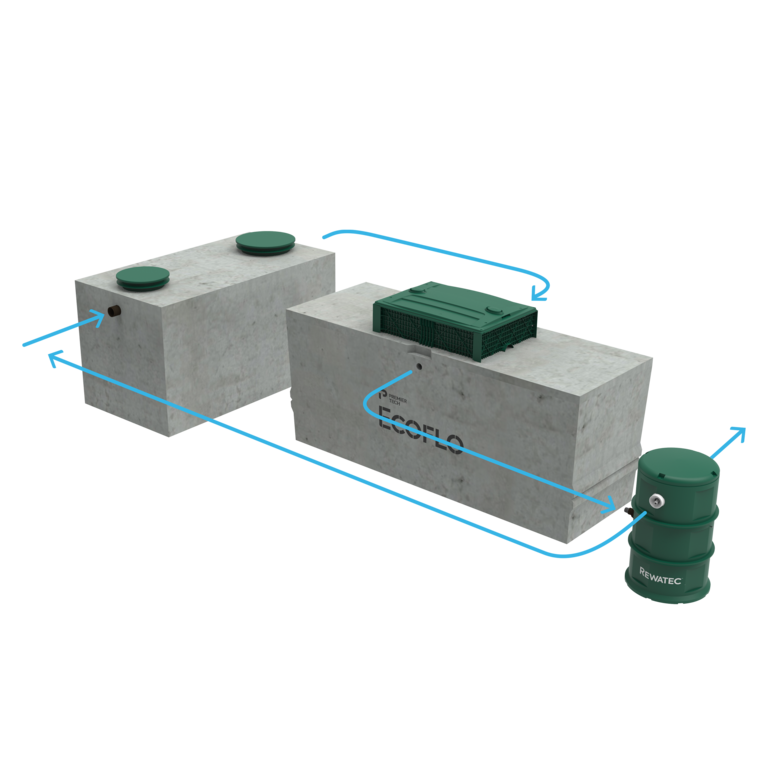

Primary treatment tank or fine screen

In typical installations, wastewater enters a primary treatment tank that allows liquids to separate from solids. Primary solids settle on the bottom of the tank and are removed by a septic pumper as often as needed.

Liquids pass through an integrated effluent filter before leaving the primary treatment tank. The filter captures suspended solids that could clog system components downstream.

Sometimes a fine screen takes the place of the primary treatment tank, acting as a simple physical barrier to remove solids from wastewater.

Equalization tank (if needed)

After primary treatment, liquids move downstream into an equalization tank. This tank collects wastewater from daily peak-use periods and sends controlled doses to the Rewatec MBR.

Rewatec MBR and final discharge

The Rewatec MBR combines two treatment processes in one tank to produce effluent that meets the most stringent standards.

In the first step, aeration cycles provide oxygen to microorganisms that feed on organic pollutants. As microorganisms increase in number, they mix with other solids to form activated sludge – the biomass that treats incoming wastewater.

Biomass remains in the tank, eventually reaching concentrations up to three times higher than those found in traditional activated sludge systems. This key feature minimizes the size of the installation, making Rewatec MBR systems the most compact solutions available.

In the second step, a low-pressure vacuum sucks wastewater through the pores of a rigid ultrafiltration membrane that blocks even the most persistent pollutants. Clarified wastewater is then pumped out of the tank and safely discharged into the environment.

The fine bubbles that aerate the biological process are also used to scour the membrane, preventing surface clogging and getting maximum value for all energy consumed.

Premier Tech’s 360° support

Local expertise is the cornerstone of our global team. Together, we have the technical understanding and industry experience to guide every phase of your project.

Design

- engineering support to guarantee the best solution

- help with technical drawings and diagrams

- advice for electromechanical equipment

- control panel design, including electrical diagrams

Construction and installation

- dedicated project managers

- fast answers to all questions

- on-site support to ensure high-quality installations

- real-time troubleshooting

Start-up

- commissioning by a qualified technician

- verification of installation success

- rapid responses to any areas of concern

Maintenance

- full support from our process and mechanical experts

- maintenance services from local technicians

- remote support available

Available models

Our impressive lineup of Rewatec MBR systems includes a wide range of tank materials, giving you a wealth of choice as your project evolves from idea to installation.

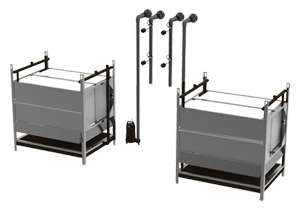

Solutions that strike the perfect balance between versatility and durability.

- personalized modular solutions

- ready-to-use options

- compact and lightweight

- indoor installations available

Rock-solid solutions for all site conditions.

- cast in place or ready to use

- suitable for clay soils

- can be installed in high groundwater

Solutions with remarkable strength-to-weight ratios.

- ready-to-use models available

- minimal final footprint

- suitable for clay soils

- can be installed in high groundwater

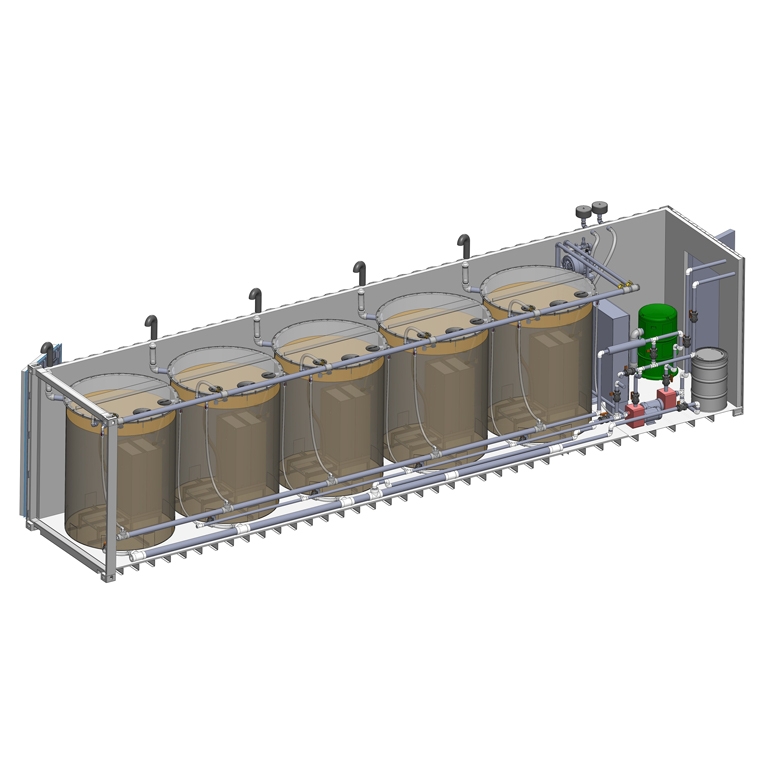

Solutions for remote projects and temporary camps.

- pre-assembled and ready to use

- easy set-up

- minimal infrastructure needed

- no excavation

Mobile solutions for remote projects and temporary camps.

- no lag between delivery and start-up

- pre-assembled and ready to use

- minimal infrastructure needed

- no excavation