What is meant by surface water drainage?

Surface water drainage occurs when accumulated precipitation on surfaces such as patios and driveways, and roads and car parks, drain away.

Surface water, which is typically caused by intensive rainfall, snow, or soil permeability, is directed to nearby drains so it can be subsequently collected in sewer systems and driven to engineered management means. In some cases, it can also be re-directed in a controlled manner into the surrounding environment (i.e. into a reed bed or a river) via a soakaway or something similar.

With the climate change phenomena becoming more apparent, the likelihood of surface water flooding via more intense and more frequent bouts of rainfall is increasing. As such, surface water drainage systems are becoming an essential infrastructure requirement to help mitigate such storm overflows and groundwater pollution.

What are SuDS?

Sustainable underground drainage systems (SuDS) are a collection of surface water management practices that are designed to mimic natural drainage and catchments. SuDS are typically applied as close to the water source as possible to manage potential flood risks, improve water quality (pollution) and ensure biodiversity in our environment.

Sustainable drainage systems aim to work with the natural environment rather than against it. A sustainable drainage system can collect and convey water and regulate runoff via attenuation before it enters a watercourse. They also provide spaces to hold water in engineered and/or natural depressions or allow groundwater and rainwater to naturally infiltrate into the earth or evaporate from the ground.

Designing sustainable drainage systems to deliver water management, biodiversity, climate change impacts control, and water regeneration, can also be a cost-effective way of delivering resilient communities in urban areas.

Local authorities, water and sewage companies, Highways England, construction companies, and infrastructure contractors who see how the requirement for SuDS meets the objectives of the wider social and environmental policy in the UK, all understand the sustainable benefits of effective surface water management.

How can I improve surface water drainage?

Intercepting water and managing surface water runoff from higher slopes to lower land is essential for the management and purification of water. Pollutants like hydrocarbons, silt, solids, and heavy metals are the most common and persistent ones. Intercepting runoff water from other sources, for example, roadside drains, carparks, neighbouring properties, and dam overflows also mandate management.

Managing contaminated surface water run-off with oil separators

Fuel/oil separators are engineered, often on a drainage area basis, to manage contaminated run-off and oil spills typically generated by the presence of stormwater.

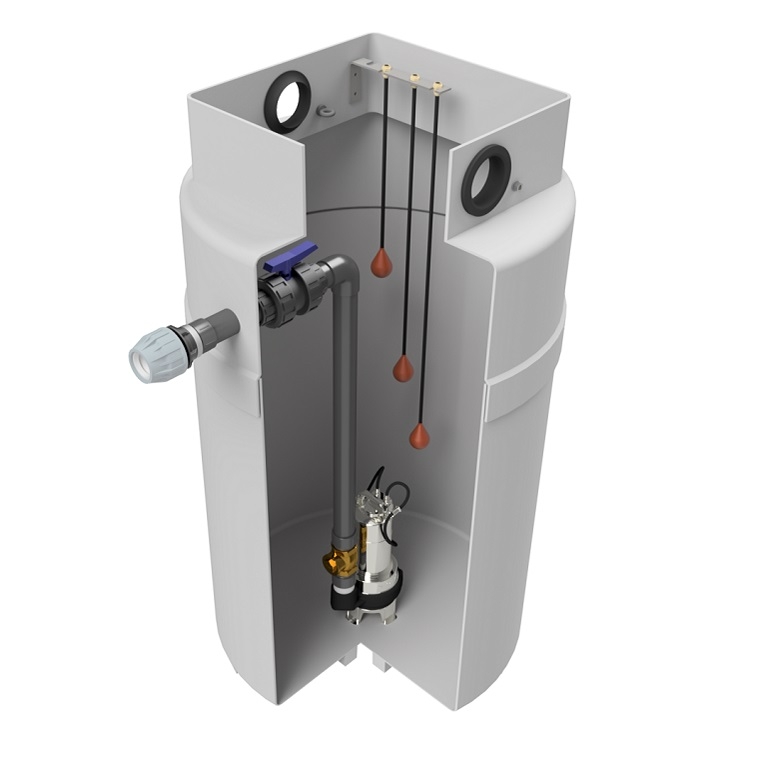

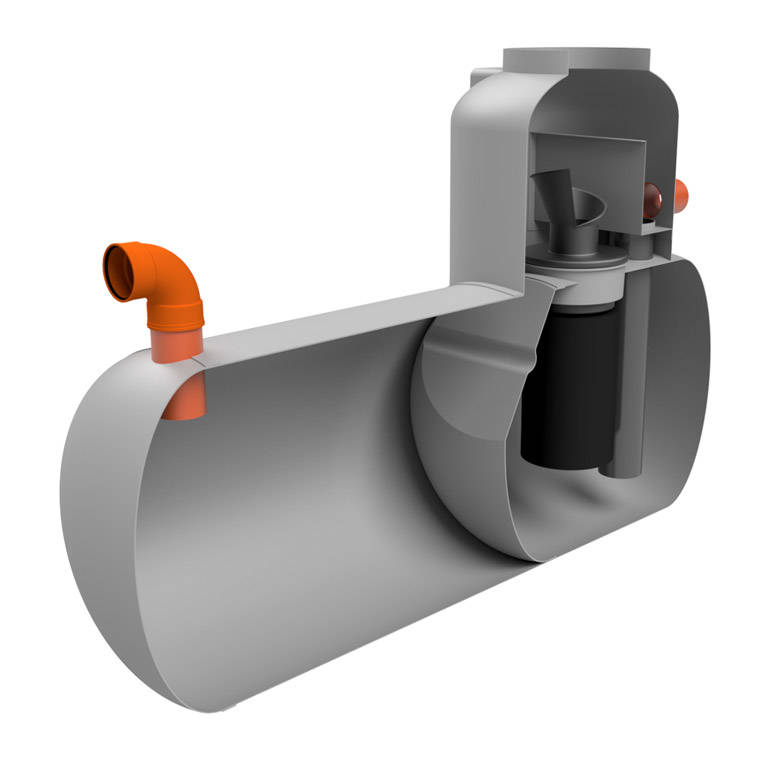

Separators, also known as interceptors, typically comprise of a single/double vessel with coalescent filters or similar oil separation mechanisms. They are installed in locations where pollution to our environment from hydrocarbons is likely, i.e. in carparks, fuel station forecourts, vehicle muster points, and roads/motorways.

Separators work by separating and then retaining oil-based contaminants from water. After the separation process, decontaminated “clean” water is released into drains, soakaways, or sewers, minimising the risk of environmental pollution. In most scenarios, effluent is directed to attenuation schemes so it can be regulated in a controlled manner toward other downstream stormwater management processes. This also helps to further mitigate the potential risk of flooding.

In addition to oil separation, separators can also purify water runoff that is rich in a large variety of pollutants. This includes the removal of metals – mainly in their particulate form, silt, and other solid debris.

Types of separators

There are three different separator types: full retention (NS), bypass (NSB), and forecourt (ANO or LNO), which all work in a similar manner.

Bypass separators

Bypass separators, which are a recognised proprietary treatment system defined by The SuDS Manual C753 as an oil separator, are suitable for use as part of the SuDS treatment train. They are designed for sites subjected to low risk of contamination (i.e. car parks) for flows up to 6.5mm/hour. This will cover 99% of all rainfall events, allowing heavier rainfalls to bypass the separator after diluting the effluent.

Full-retention separators

Full-retention separators, which are also a recognised proprietary treatment system defined by The SuDS Manual C753 as an oil separator, are required in locations that experience heavier rainfalls and/or in areas that are at a high risk of contamination (i.e. service stations, vehicle maintenance sites, etc.).

Forecourt separators

Lastly, forecourt separators, are required at petrol stations and other fuel-related sites. They are expected to retain an entire tanker truck’s fuel spill, up to a capacity of 7,600 litres.

Need help with a rainwater management project?

Send us a few quick details and we'll give you free advice and recommendations based on your needs.