Energy-free treatment

Energy-free treatment

Sustainable system of choice

Sustainable system of choice

Installed for life

Installed for life

Silent and discreet

Silent and discreet

What is the Ecoflo biofilter?

The Ecoflo biofilter is the most sustainable wastewater treatment system on the market thanks to its 100% natural, renewable, and compostable coco filter.

This simple, compact, and energy-free solution can help you meet Irish wastewater regulations in one of two ways:

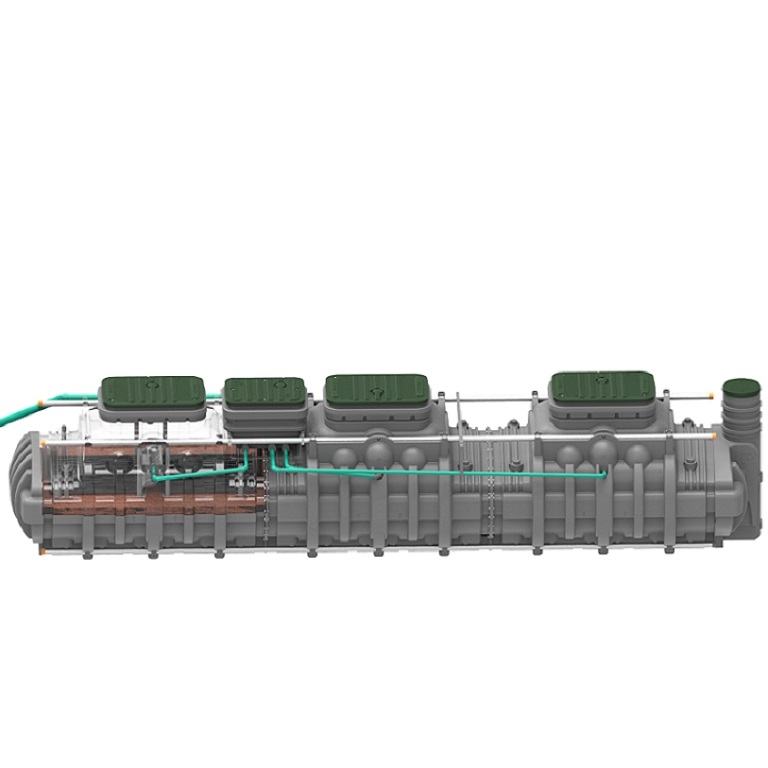

- Secondary treatment: The unit receives effluent from your septic tank and cleans it to a higher standard. Models for this use are available for 5 to 50 PE (population equivalent).

- Tertiary treatment: The unit receives effluent from another sewage treatment plant and polishes it to meet the most stringent environmental standards. Models for this use are available from 16 PE and up.

Ecoflo gives you peace of mind that you're choosing a proven and reliable solution. It is fully certified to meet EN12566-3 for secondary treatment, EN12566-6 for use after septic tanks that are in compliance with EN12566-1 and EN12566-7 for tertiary treatment. All our products are compliant with S.R. 66:2015.

This system is ideal for:

- homes and rural holiday cottages

- singular and multiple glamping sites

- camping sites

- hotels

- golf courses and off-grid sporting facilities

- off-grid locations

Ecoflo is the sustainable septic solution

Premier Tech Water and Environment transforms coconut husk fragments into an effective filtering medium, giving new life to a valuable resource and ensuring no part of the coconut tree goes to waste.

Thanks to the organic nature of coconut husks, our all-natural filter is both renewable and fully compostable.

This makes our filter the eco-friendly solution for treating wastewater — one that continues to protect the environment even after its use.

How does the Ecoflo biofilter work?

The Ecoflo system filters wastewater through all-natural coconut husk fragments. No energy is required for treatment, making this sewage treatment plant the sustainable and economical system of choice.

Step 1: Wastewater inflow

Wastewater flows from your septic tank or secondary wastewater treatment system into the Ecoflo biofilter for additional treatment.

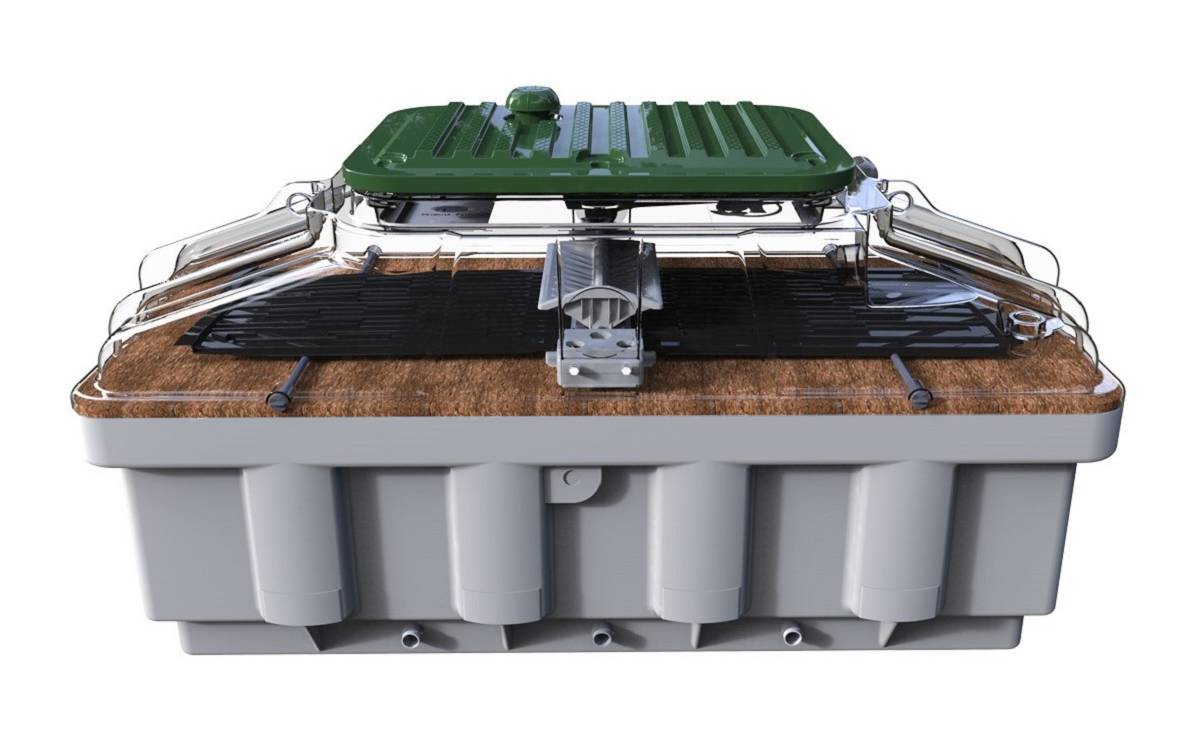

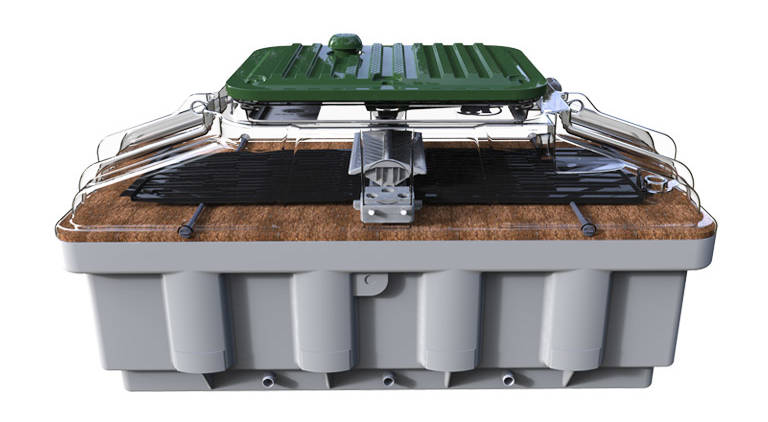

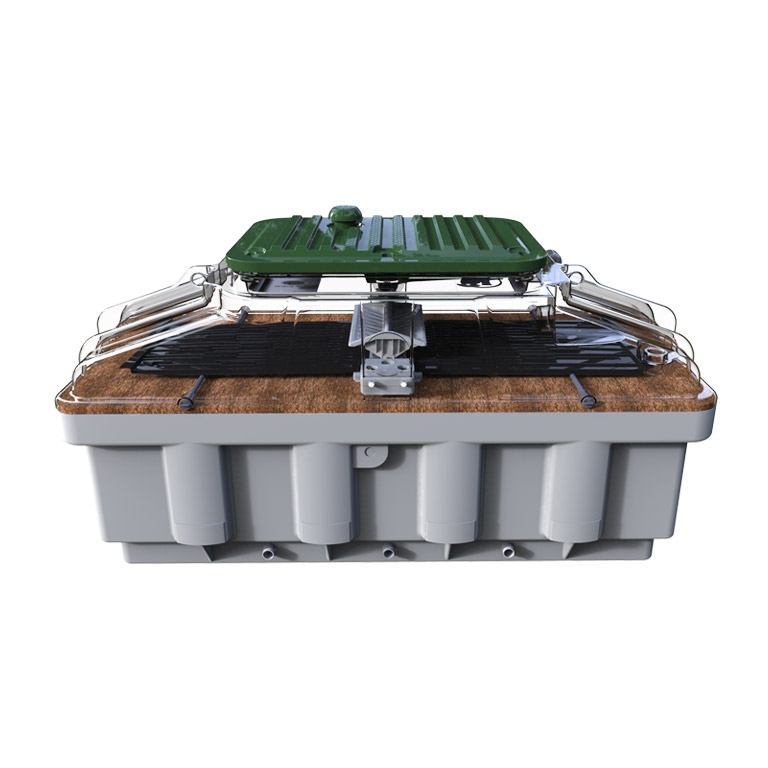

Step 2: Non-mechanical tipping bucket

Inside the Ecoflo biofilter, a non-mechanical tipping bucket scatters wastewater across perforated distribution plates. These plates allow wastewater to evenly trickle across the coco filter.

Step 3: Coco filter

The coco filter is the heart of the Ecoflo biofilter. It creates a physical treatment barrier that cleans effluent to an even higher standard.

Step 4: Final discharge

After percolating through the all-natural coco filter, wastewater is then discharged directly to a correctly sized stone bed or to an off-set stone bed.

Premier Tech services the Ecoflo biofilter

We offer a full range of services for the Ecoflo biofilter. From helping you choose the ideal model to commissioning and maintenance, we’ve got you covered.

After your system is installed, we maximise the lifespan of your coco filter and protect your investment in your Ecoflo biofilter by offering:

- coco filter renewals (usually after 10 to 15 years of use)

- refurbishments

- spare parts

Get in touch with our team to ensure your system performs at the highest level, now and for years to come.

Premier Tech's warranty for the Ecoflo biofilter

Since 1995, we have installed thousands of Ecoflo biofilter units across the globe, helping to protect, improve, and regenerate our planet.

Our experience in the industry allows us to give you a complete warranty for the Ecoflo biofilter, including a renewable 10-year guarantee on the coco filter and a 25-year guarantee on the shell and construction.

Ecoflo biofilter guides and manuals

Manual and installation guide (4 PE - 18 PE)

Available products

We offer a complete range of Ecoflo septic systems to meet your needs. Wherever your site, we have the right product to transform any challenge into a tailor-made solution.

- Suitable for 4 to 50 PE

- Direct discharge or pumped if required

- Suitable for 16 to 200 PE

- Units can be combined for larger PE requirements

- Direct discharge or pumped if required

- Splitter chambers available